The Modern society today demands competent, long lasting, and versatile materials given the current technological advancement. One such advancement that has been making waves in a variety of industries is Tech Flex Heat Resistant solutions. These products for high temperature applications and better mechanical performance are now finding applications in electronic, automotive industries, and even more.

In this article, we will explore the core features of Tech Flex Heat Resistant products, their uses in different industries, and practical advice on choosing the right heat-resistant material for your needs.

What is Tech Flex Heat Resistant?

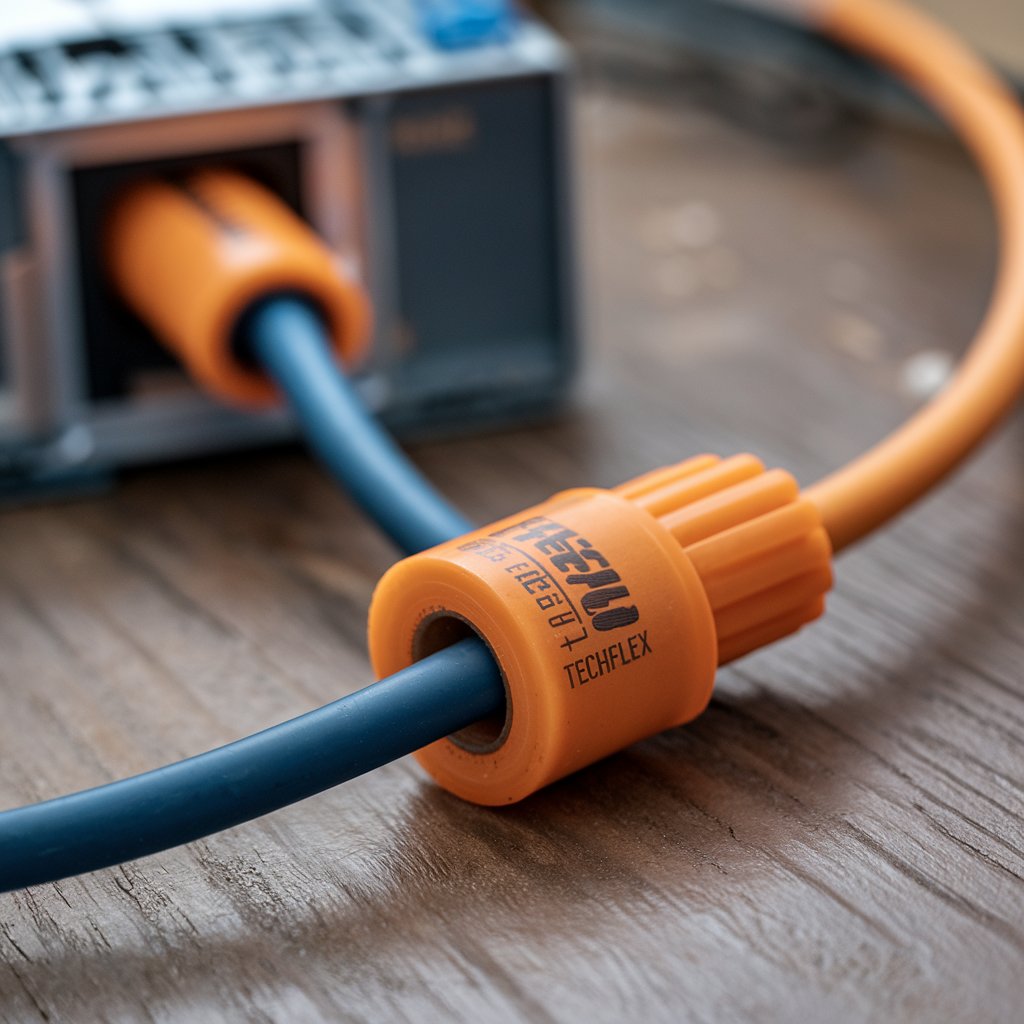

Tech Flex Heat Resistant refers to flexible sleeving or tubing designed to endure high temperatures without compromising its structural integrity or function. Usual materials include silicone, fiberglass or certain polymer composites; these can withstand temps which would normally cause molting, breakdown or ineffectiveness with commonplace plastic rubber goods. These convenience are achieved by the ability of these products to offer flexibility with heat resistance, thus proving vital in industries operating under extreme conditions or in applications suited for enhanced protection. Whether it’s to safeguard wiring in electrical equipment or to protect critical components in high-performance machinery, Tech Flex Heat Resistant solutions are increasingly becoming a go-to choice.

Key Features of Tech Flex Heat Resistant Products

1.High Temperature Tolerance

One of the most critical features of Tech Flex Heat Resistant solutions is their ability to tolerate extreme heat. They are intended to operate at temperatures which may be over 200 C (392 F) and, at times, peak temperatures somewhat higher. This makes them suitable for use where normally used materials would prove to be ineffective.

2.Flexibility and Strength

One more important advantage of these products is the ability to use them where space is limited, when it is necessary to cover curves, or when the system involves a large number of product applications. All the same, they have the strength and rigidity necessary to avoid tearing, cracking, or worsening when under stress or when asked to move. This is especially so for industries such as automobile, aircraft, and electronics since the parts usually undergo rigorous heat and vane type motion.

3.Chemical and Flame Resistance

Tech Flex Heat Resistant materials are often engineered to be resistant not only to high temperatures but also to chemicals, oils, and even flames. This extra surface protection is important in such uses like in electrical wiring because they come into contact with chemicals or sources of fire.

4.Durability is essential for an electric vehicle especially one designed to ply in harsh environment pulling load.

Along with heat and chemical endurance, these products must be highly resilient where mechanical stress, ultraviolet light or water may be imposed. This durability helps in extending the cycle time that such equipments or systems may take before they can be replaced or repaired again.

Applications of Tech Flex Heat Resistant Solutions

The versatility of Tech Flex Heat Resistant materials means they are used across a wide array of industries. Below are some of the most common sectors where these solutions play a crucial role:

1.Automotive Industry

The application of thermal protection is important in the motorcycles where there are occasions that engines and other mechanical parts are exposed to high temperature most of the time. Tech Flex Heat Resistant sleeving is commonly used to shield wires, hoses, and cables from the heat generated by engines and exhaust systems. This is very important to guarantee that electrical systems operate as they are supposed to and reduce chances of them emitting heat and experiences electrical faults.

2.We can make Electronics part of our own home by providing us with Electronics and electrical wiring.

Printed circuit boards used in electronics are very susceptible to heat and if exposed to high temperatures, for instance in a car boot, they may develop short circuits or cause destruction of the equipment in use. Heat shrinkable sleeving applied around the wires and cables offer safeguard against heat produced by electric carrying currents and other heat bearing objects. This is particularly important in high-performance technologies such as computers and information processing servers as well as industrial products.

3.Aerospace and Aviation

Aerospace industry involve the use of materials that provide safeguard, effectiveness and sturdiness in tough operations. Tech Flex Heat Resistant materials are frequently used to protect wiring, tubing, and other critical components from both high temperatures and potential chemical exposure, ensuring that aircraft and spacecraft operate safely at high altitudes and in variable environmental conditions.

4.Industrial Machinery

A number of industries exist where heavy plant and equipment for the production line is exposed to high temperature environments for instance manufacturing industries. Protective heat resistant sleeves are put on every part of this machinery for example; on the sensors cables and hydraulic hoses in that way they can function efficiently without failing or amorphing off.

Choosing the Right Tech Flex Heat Resistant Material

When it comes to selecting the right heat-resistant product for your application, several factors should be considered:

1.Temperature Requirements

First, one must know the service temperature of the material; that is, what range of temperatures the material would be subjected to. This products come in various temperature ratings, so make sure to choose one that meets or exceeds the maximum temperatures your application will encounter.

2.Flexibility Needs

In more specific terms, the versatility of the product may nevertheless be another vital consideration based on where and in what ways the material is to be used. In the compounded or confining circuit situations, it is necessary to select a material to wrap the element that will be able to flex and perform shielding functionality.

3.Chemical Exposure

If your system or machinery is subjected to chemical, oil or solvent, you need to check whether the heat-resistant product of your choice will not degrade or cease to function the moment it comes into contact with the substance in question.

4.Durability and Lifespan

Last, you need to look at the robustness and the life span expected for the product in the environment it will be placed in. In industries like aerospace or automotive, where components must endure long-term stress and harsh conditions, investing in higher-quality, more durable Tech Flex Heat Resistant solutions can save time and costs in the long run.

Conclusion

Tech Flex Heat Resistant solutions are increasingly indispensable in today’s technology-driven industries. Temperature stability, flexibility, and chemical as well as fire resistance make them suitable for almost any application: from the automotive industry to aerospace. Thanks to technological advancements, industries are continuously seeking materials for applications that deliver excellent performance and unique characteristics, and as such, the need for high-performance materials is expected to increase. By understanding the specific needs of your application—whether it’s temperature tolerance, flexibility, or chemical resistance—you can make an informed decision on the best Tech Flex Heat Resistant product to ensure safety, efficiency, and long-term durability.